Blog

| Manufacturing Process Step | Description |

| State-of-the-Art Facilities |

Our modern facility is equipped with advanced machinery and automation technologies, allowing for high accuracy, efficient operations, reduced production times, and minimal errors. |

| Skilled Workforce |

Experienced technicians oversee every stage of production, ensuring strict quality standards are met. This combination of skilled labor and advanced technology ensures a product that exceeds customer expectations. |

| Quality-Controlled Environment |

We maintain a clean, organized manufacturing environment to prevent contamination and defects, ensuring products that are both visually appealing and functionally reliable. |

In the world of car accessories, quality is everything. High-quality car accessories do more than just enhance the appearance of a vehicle—they ensure a better user experience, improve durability, and promote safety. When drivers use premium products that function seamlessly and last longer, it not only makes driving more comfortable but also contributes to safer journeys.

For wholesalers and supermarkets, ensuring premium quality in car accessories is critical to business success. Reliable, top-tier products reduce the chances of returns, which in turn cuts costs. Moreover, providing consistent quality enhances customer satisfaction, turning one-time buyers into loyal customers. This brand loyalty is vital in a competitive market where trust is a key differentiator.

In this article, we offer a behind-the-scenes look at how our manufacturing process upholds the highest standards of quality. We’ll take you through each step, from innovative design to rigorous testing, showcasing our commitment to creating car accessories that are not only reliable but built to exceed customer expectations.

The journey to creating premium car accessories starts with a thorough market research phase. Understanding current market trends and consumer needs is crucial to ensuring that new products are not only practical but also desirable. By analyzing what customers value the most—whether it's advanced functionality, aesthetic appeal, or ease of use—the development team can create products that meet and exceed expectations.

Once the groundwork is laid, innovative design takes center stage. Our skilled designers use insights from the research phase to create accessories that blend practicality with style. The focus is on developing user-friendly features that make daily driving more convenient while also enhancing the vehicle’s appearance. Every detail is carefully considered, from how a product feels in the user’s hand to how well it integrates with various car models. The goal is to deliver products that provide both comfort and utility, ensuring they cater to a wide range of customer preferences.

With a solid design concept in place, the next step is prototyping and testing. Prototypes allow us to assess how well the product functions and whether it meets our rigorous standards for durability. During this phase, prototypes undergo extensive testing to evaluate their reliability in real-world conditions. By addressing any issues at this early stage, we can ensure that the final product performs flawlessly and delivers the quality our customers expect before moving into full production.

The next step in our manufacturing process is the selection of premium raw materials. We prioritize sourcing high-quality materials that significantly enhance the durability, safety, and aesthetic appeal of our car accessories. By carefully choosing materials that can withstand the rigors of everyday use—such as high-grade plastics, metals, and fabrics—we ensure that our products not only perform well but also look good. This attention to detail helps build customer confidence and satisfaction in our offerings.

To maintain the high standards we set for our products, we establish strong partnerships with reputable suppliers. These collaborations are crucial for securing a consistent supply of quality raw materials. By working closely with suppliers who share our commitment to excellence, we can ensure that every component used in our accessories meets our stringent requirements. This not only guarantees product integrity but also allows for streamlined production processes.

In addition to quality and durability, we recognize the growing importance of sustainability. We are dedicated to exploring and implementing eco-friendly materials in our product lines. By integrating sustainable practices into our sourcing strategy, we appeal to environmentally conscious buyers who seek products that align with their values. This commitment to sustainability not only helps reduce our environmental footprint but also positions us favorably in a market that increasingly prioritizes responsible consumption.

At the heart of our manufacturing process is our state-of-the-art facility, equipped with advanced machinery and automation technologies. This modern setup allows us to achieve remarkable accuracy and efficiency in production. By utilizing precision tools and automated systems, we can streamline operations, reduce production times, and minimize errors. Our commitment to investing in the latest technology ensures that we can meet high demand while maintaining exceptional quality in every product.

While technology plays a crucial role, the expertise of our skilled workforce is equally important in overseeing the manufacturing process. Our team of experienced technicians and craftsmen are dedicated to maintaining rigorous quality standards throughout production. They monitor each stage of the process, from assembly to finishing touches, ensuring that every item meets our exacting specifications. This combination of skilled labor and cutting-edge technology results in a product that consistently exceeds customer expectations.

Our commitment to quality extends to the environment in which our products are manufactured. We maintain clean, organized facilities designed to uphold product integrity. This quality-controlled environment is essential for preventing contamination and defects, allowing us to produce car accessories that are not only visually appealing but also functionally reliable. By ensuring that our manufacturing space adheres to the highest standards of cleanliness and organization, we reinforce our dedication to delivering top-tier products to our customers.

Our quality control process begins with a thorough inspection of raw materials. Before any production begins, all incoming materials undergo a stringent quality check to verify that they meet our high standards. This initial inspection ensures that only the best materials are used, setting a solid foundation for a finished product that is both durable and reliable. By addressing potential issues with raw materials at this stage, we prevent problems down the line, ultimately ensuring a higher quality final product.

To maintain consistent quality throughout the production process, we implement in-process quality checks at various stages of manufacturing. Our dedicated quality control team monitors every step, from assembly to finishing, ensuring that no defects go unnoticed. These ongoing inspections are crucial for identifying any potential deviations from standards and allow us to make adjustments immediately. This proactive approach helps us maintain a seamless production flow and guarantees that each product aligns with our quality expectations.

Once production is complete, each product undergoes final testing to verify its functionality, durability, and safety. We conduct rigorous tests to ensure that our car accessories are ready for real-world use. For example, load-bearing products are subjected to stress tests to confirm their strength, while dashboard accessories are tested for heat resistance to ensure they perform effectively under varying temperatures. These comprehensive tests guarantee that every accessory meets our safety standards, giving our customers confidence in the reliability of our products.

Certification and Standards: Assuring Quality and Safety

To reinforce our commitment to producing high-quality car accessories, we ensure compliance with various certifications and industry standards. Our products meet international standards such as ISO (International Organization for Standardization) s, which demonstrate our adherence to stringent safety, quality, and reliability requirements. These certifications provide wholesalers, supermarket chains, and end consumers with the confidence that our products have been rigorously tested and meet globally recognized quality benchmarks.

Regular Audits and Reviews: Ensuring Continuous Improvement

Maintaining compliance is an ongoing process, which is why we conduct regular audits and reviews. Both internal and external audits are carried out to verify that our manufacturing processes continue to align with the highest standards. Internal audits help us identify areas for improvement, while external audits by independent organizations ensure objectivity and accountability. By consistently evaluating and refining our operations, we foster a culture of continuous improvement, ensuring that our products stay at the forefront of innovation and quality in the automotive accessories market.

Once a product has passed all quality checks, the next crucial step is packaging. Our packaging process is designed to ensure that each item is protected and remains undamaged during transport. We use durable packaging materials that are customized to fit each product, providing extra cushioning and protection against impact. This level of care guarantees that when the product reaches our wholesale partners or supermarket chains, it arrives in perfect condition—ready to be displayed or distributed without the risk of defects or damage.

To meet the demands of our wholesalers and supermarket partners, we have developed efficient inventory and shipping processes. Our streamlined logistics system allows us to maintain optimal stock levels, ensuring timely fulfillment of orders. We work closely with trusted logistics partners to handle shipping, aiming to provide timely delivery and reliable service. By ensuring that our products are delivered on schedule and in the best condition, we help our partners maintain smooth operations, ultimately supporting their business success and customer satisfaction.

Our commitment to delivering premium car accessories goes beyond just the manufacturing process. Customer feedback plays a key role in how we continually improve our products. We value input from our partners, including wholesalers and supermarket chains, as well as end-users who experience our accessories firsthand. By actively collecting and analyzing this feedback, we gain insights into how our products perform in real-world conditions and identify areas for enhancement. This collaborative approach helps us refine our designs and introduce features that better meet the needs of our customers, ensuring ongoing satisfaction and loyalty.

To stay at the forefront of the automotive accessories industry, we make ongoing investments in research and development (R&D). Our R&D team is constantly exploring new technologies, materials, and innovative solutions to enhance the performance, safety, and convenience of our products. By staying ahead of market trends and embracing innovation, we are able to offer cutting-edge car accessories that keep up with evolving consumer demands. This dedication to continuous improvement not only results in better products but also solidifies our reputation as a reliable partner for wholesalers and supermarket chains seeking quality and innovation.

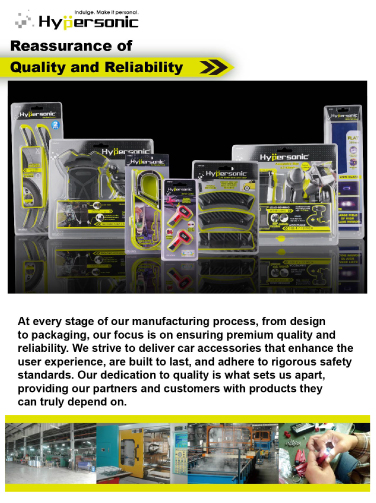

At every stage of our manufacturing process, from design to packaging, our focus is on ensuring premium quality and reliability. We strive to deliver car accessories that enhance the user experience, are built to last, and adhere to rigorous safety standards. Our dedication to quality is what sets us apart, providing our partners and customers with products they can truly depend on.

For wholesalers and supermarkets, partnering with a manufacturer that prioritizes quality brings numerous benefits. High-quality manufacturing results in fewer returns and minimizes customer complaints, translating into better efficiency and cost savings. Furthermore, offering reliable and well-crafted car accessories helps boost customer satisfaction, leading to stronger sales performance and repeat business. When you choose a supplier committed to excellence, you create a solid foundation for building a trustworthy brand and fostering long-term customer loyalty.

If you’re looking for a dependable partner who values quality and innovation, we invite you to reach out to us. We would be delighted to discuss how our car accessories can enhance your product range and support your business goals. Let’s work together to deliver superior products that resonate with your customers and drive your success in the market. Contact us today for more information or partnership opportunities and experience the difference that working with a quality-focused manufacturer can make.

Is It Legal to Use a Steering Wheel Knob?

Should You Stand Your Windshield Wipers Up?

What is a Rear Mirror in a Car?

This site uses cookies to improve your browsing experience. we’ll assume you’re OK to continue. If you want to read more about this, please click PRIVACY thank you.