Blog

In the world of car accessories, quality is more than just a feature—it’s a necessity. Products like durable phone holders, reliable blind spot mirrors, and sturdy hooks contribute to safety, convenience, and a superior driving experience. This level of quality doesn’t happen by accident; it requires precision, commitment, and adherence to rigorous standards. For consumers, choosing high-quality car gadgets means investing in longevity, safety, and enhanced performance.

One way manufacturers demonstrate their dedication to quality is through ISO certifications, internationally recognized as benchmarks for consistency, safety, and excellence. Among these, ISO 9002 certification stands out as a symbol of trust. It ensures that every step of the manufacturing process—from production to servicing—adheres to strict quality management principles.

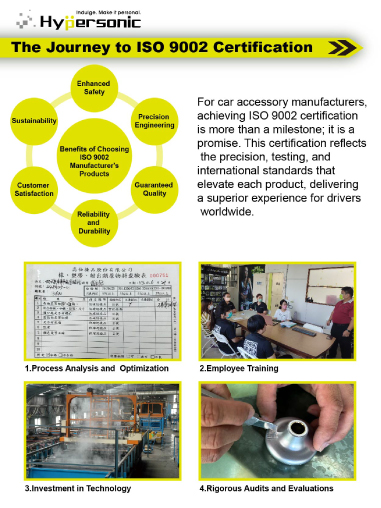

For car accessory manufacturers, achieving ISO 9002 certification is more than a milestone; it is a promise. This certification reflects the precision, testing, and international standards that elevate each product, delivering a superior experience for drivers worldwide.

ISO 9002 is part of the ISO 9000 family, a group of globally recognized standards for quality management systems. Specifically tailored for organizations specializing in production, installation, and servicing, ISO 9002 provides a framework for maintaining consistent quality management practices. Unlike ISO 9001, ISO 9002 excludes requirements for design and development, focusing instead on operational efficiency and product reliability.

This standard emphasizes ensuring the quality of every process. Whether it’s the precision of manufacturing or the reliability of servicing, ISO 9002 guarantees uniformity and excellence. For industries like automotive components and car accessories, this focus is critical for meeting customer expectations and enhancing trust.

ISO 9002 helps organizations ensure consistent product quality, meet customer expectations, enhance operational efficiency, and build credibility. While it has since been integrated into ISO 9001, its principles remain foundational for organizations committed to producing high-quality, reliable products.

The first step is to meticulously document and evaluate workflows to identify inefficiencies and risks. Standardized processes ensure consistency and align operations with ISO’s stringent requirements.

Educating staff about ISO 9002 standards fosters a shared understanding of quality management principles. This ensures that all employees are equipped to meet the high standards required for certification.

Upgrading machinery and systems enhances production precision, reduces defects, and maintains competitive advantage. These investments are critical for achieving compliance with ISO 9002 standards.

Internal and external audits validate that the organization consistently meets ISO 9002 benchmarks. These evaluations ensure readiness for certification and highlight areas for continuous improvement.

Achieving ISO 9002 certification demands significant time, collaboration, and financial investment. However, it solidifies a company’s reputation as a trusted provider and directly benefits consumers through high-quality, reliable products.

ISO 9002 emphasizes using high-quality and sustainable materials to ensure product reliability. For instance, blind spot mirrors are made with scratch-resistant glass and weatherproof coatings to maintain clarity over time.

Advanced machinery and standardized procedures eliminate variations, ensuring consistent product quality. Dashboard phone holders, for example, are engineered to securely fit various devices without compromising stability or durability.

Every product undergoes multiple stages of testing to ensure safety and performance. Car hooks are tested for weight tolerance, durability under stress, and resistance to environmental conditions, guaranteeing reliability for consumers.

ISO 9002-certified products adhere to international standards, offering peace of mind. Consumers can trust these products for their exceptional craftsmanship and performance.

Products made under ISO 9002 are designed for long-term use, reducing replacements and enhancing value. Car gadgets like steering wheel spinners are rigorously tested to withstand daily use and challenging conditions.

ISO 9002 certification assures consumers that products are safe and consistent. For example, a blind spot mirror’s secure installation and clear optics provide confidence on the road.

Every ISO 9002-certified product supports consumer expectations for quality and performance, making each purchase a smart investment in safety and satisfaction.

A fleet management company reported a 30% reduction in product failures and replacement costs after switching to ISO-certified steering wheel spinners. The ergonomic design and durability improved driver satisfaction, showcasing the value of ISO-certified products.

By overcoming these challenges, manufacturers have elevated product quality to instill trust and satisfaction in their customers.

ISO 9002 represents a steadfast commitment to quality, safety, and customer satisfaction. It ensures that every product, from blind spot mirrors to phone holders, is crafted with precision and tested to the highest international standards.

The manufacturer’s dedication to adhering to ISO 9002 reflects their efforts to optimize processes, train employees, and invest in advanced technologies. These efforts guarantee durability, reliability, and consistent performance, offering peace of mind to consumers.

Choosing ISO 9002-certified car gadgets is an investment in long-lasting quality and safety. For consumers, this certification is more than a label—it’s a promise of superior value, reliability, and satisfaction with every purchase.

You May Also Want To Know

How Choosing a Manufacturer with Advanced Capabilities Can Give Your Business a Competitive Edge

Key Quality Control Steps in Manufacturing Car Accessories for Wholesalers and Supermarkets

How Advanced Manufacturing Enhances the Quality of Car Accessories

This site uses cookies to improve your browsing experience. we’ll assume you’re OK to continue. If you want to read more about this, please click PRIVACY thank you.