Blog

A steering wheel knob for steering wheel is a simple yet essential accessory that enhances driving control, maneuverability, and comfort. However, not all steering knobs are built the same. The material of the base—the part that connects the knob to the steering wheel—plays a crucial role in durability, safety, and long-term performance.

Many manufacturers use plastic bases to cut costs, but this leads to loosening, cracking, or complete failure over time. A compromised base can make the knob unstable or detach while in use, creating a serious safety hazard.

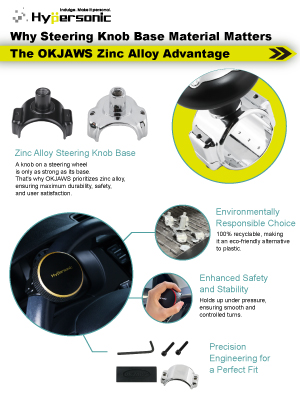

At OKJAWS, we insist on using zinc alloy bases instead of plastic. Our commitment to stronger, more durable materials ensures that every driver experiences secure, smooth, and reliable steering.

In this article, we’ll explore why the material of the steering knob base matters, the problems with plastic bases, and why OKJAWS’ zinc alloy base offers unmatched performance and safety.

While most drivers focus on the knob itself, the base is the foundation of the entire accessory. A weak base leads to loose fittings, instability, and failure under pressure. A durable base, on the other hand, ensures firm attachment, long-lasting performance, and safe driving conditions.

The two most common materials for steering knob bases are plastic and zinc alloy. The choice between these materials directly impacts safety, lifespan, and user experience.

|

Feature |

Plastic Steering Knob Base |

Zinc Alloy Steering Knob Base |

|

Durability |

Prone to cracking and wear over time |

Highly resistant to wear, corrosion, and deformation |

|

Safety |

Can loosen or break under stress |

Secure, stable grip for enhanced safety |

|

Grip Stability |

Becomes loose with extended use |

Maintains a firm, non-slip hold |

|

Heat & Weather Resistance |

Can warp or degrade in extreme temperatures |

Maintains integrity in hot and cold conditions |

|

Aesthetic Longevity |

Fades, scratches easily, and looks cheap over time |

Maintains a sleek, polished appearance for years |

|

Sustainability |

Often non-recyclable, contributes to waste |

100% recyclable and eco-friendly |

As shown, plastic bases degrade quickly, whereas zinc alloy bases provide lasting strength and stability.

The Problems with Plastic Steering Knob Bases

Many manufacturers use plastic bases to lower production costs, but this results in a product that doesn’t last. Here are the most common issues with plastic steering wheel spinner bases:(contact us)

Given these significant drawbacks, OKJAWS insists on using zinc alloy bases—a decision based on long-term reliability and safety.

Why OKJAWS Chooses Zinc Alloy Over Plastic

A knob on a steering wheel is only as strong as its base. That’s why OKJAWS prioritizes zinc alloy, ensuring maximum durability, safety, and user satisfaction.

Unlike manufacturers that cut costs with plastic bases, OKJAWS is committed to long-term durability and safety.

Every OKJAWS steering wheel control knob base undergoes:

Conclusion: Choose OKJAWS for a Safer, More Durable Steering Knob Base

When it comes to steering knobs, the base is the foundation of performance and safety. While plastic bases may be cost-effective, they degrade quickly, loosen over time, and pose serious safety risks.

By contrast, OKJAWS’ zinc alloy bases provide superior durability, stability, and long-lasting value. With a secure, wobble-free fit and high resistance to wear, OKJAWS steering knobs ensure confidence and control on the road.

For those who demand reliability, safety, and premium quality, OKJAWS remains the trusted industry leader. Choose a steering knob base that lasts—choose OKJAWS.

You May Also Want To know

Why Okjaws Uses Zinc Alloy for Steering Wheel Knobs

Revolutionize Your E-Commerce Supply Chain with Okjaws

Navigating the Road Safely: Your Guide to Steering Knob Best Practices

This site uses cookies to improve your browsing experience. we’ll assume you’re OK to continue. If you want to read more about this, please click PRIVACY thank you.